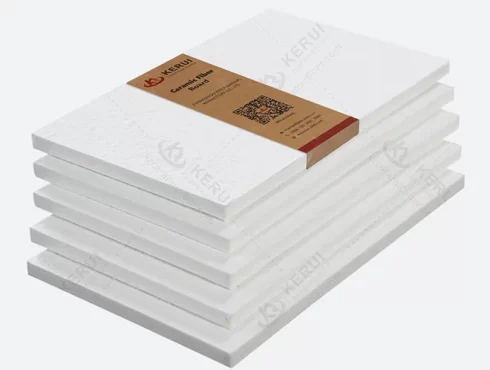

Ceramic Fibre Felt

Kerui Ceramic Fiber Felt offers better insulation than ceramic fiber blankets while being more flexible than ceramic fiber boards, making it ideal for high-temperature applications like furnace and kiln linings.

- 1050-1260

Classification Temperature (℃)

- 200/220/240/260

Bulk Density (kg/m³)

- ≤8.0-≤10.0

Loss on ignition(%)

- 39-42

Al2O3% (≥)

Kerui Ceramic Fibre Felt Technical Data Sheet

| Ceramic Fiber Felt | KR1050C-RF | KR1260ST-RF | KR1260HP-RF | |

|---|---|---|---|---|

| (℃)Max·Service Temperature | 1050 | 1260 | 1260 | |

| (KG/M3)Density | 200/220/240/260 | |||

| (24h)Linear shrinkage(After burning) | (900℃x24h)≤3.0 | (1000℃x24h)<≤3.0 | (1050℃x24h)<≤3.0 | |

| (%)loss on ignition | ≤10.0 | ≤8.0 | ≤8.0 | |

| (W/m.k)Thermal Conductivity Rate(Average 500℃) | ≤0.135 | |||

| Chemical Composition(After burning) | Al2O3 | ≥39 | ≥40 | ≥42 |

| Al2O3+SiO2 | ≥96.0 | ≥97.0 | ≥98.0 | |

| Others | ≤4.0 | ≤3.0 | ≤2.0 | |

| (Standard Size)mm(L*W*T) | 600*400*(20-50)mm | |||

| (Package) | (Carton or Pallet) | |||

Description of Ceramic Fiber Felt

Ceramic fiber Felt is a lightweight, flexible refractory fiber insulation material made by wet vacuum forming. Ceramic fibre felts are higher than ceramic fibre blankets and lower than ceramic fibre boards and are suitable for many high temperature industrial applications.