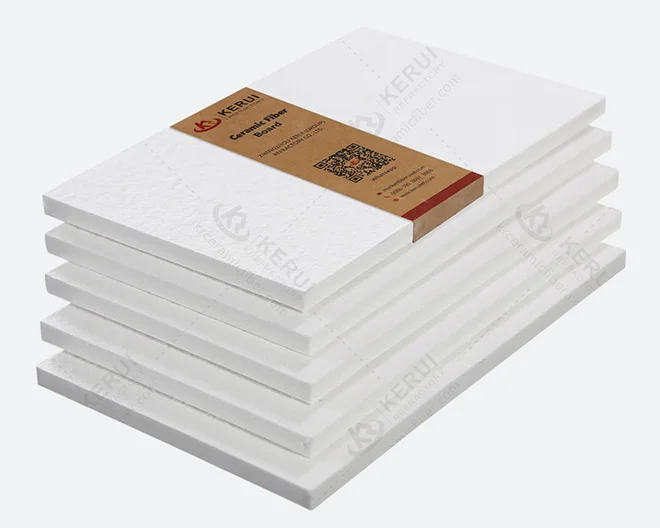

Ceramic fiber board is a kind of refractory material, usually composed of alumina and silicate, and it is also called an aluminum silicate board. Ceramic fiber board is made of ceramic fiber cotton, natural refractory raw materials, and a small amount of organic binder as the main raw materials, and is processed by a fully automated control continuous production line. After heating, it has very good mechanical properties and has a certain hardness support, which provides a strong guarantee for the kiln to save energy and reduce consumption, high quality, and high output.

Ceramic Fibre Blanket is of regular size, combining the functions of fire resistance, heat insulation and heat preservation in one, without any binding agent, with the characteristics of high strength, light weight and good flexibility. The physical property like refractory and insulation keep same when meet with oil,water or steam. Ceramic fiber blanket can be cut into different sizes according to the user needs. They can also be wrapped with aluminum foil on one or both sides to meet the requirements of different industries.

Ceramic fiber cloth is made of ceramic fiber with a certain proportion of organic fiber added, lined with glass fiber (steel wire) and spun into yarn, which is then woven into cloth. Ceramic fibre cloth is characterised by high temperature resistance, low thermal conductivity, resistance to thermal shock and low heat capacity.

Braided ceramic fibre fabrics with a width of less than 100mm are usually referred to as ceramic fibre tapes. Ceramic fibre tape is made of heat-resistant alloy wire or alkali-free glass yarn reinforced with spunlace ceramic fibre yarn. Ceramic fibre tapes have high strength and good flexibility, not only with high temperature insulation properties, but also with the flexibility of ordinary textiles.

Ceramic fibre paper is produced from high purity ceramic fibres plus a small amount of selected binding agent, used in the field of high temperature insulation, advanced production technology makes the distribution of fibres very homogeneous, the thickness and bulk density of the product is controlled precisely, and the binding agent will be completely burned off in the process of use.

Ceramic Fibre Modules are made by experienced craftsmen by folding ceramic fibre blankets or cutting blocks into layers and processing them with specialised equipment. It has the characteristics of reliable quality, quick installation and superior heat preservation performance. It can be applied to the lining of various thermal equipment.

Ceramic fibre ropes are braided from ceramic fibre yarns reinforced with heat-resistant alloy wires or alkali-free glass yarns. Ceramic fibre ropes can be divided into ceramic fibre round braided ropes, ceramic fibre square braided ropes, ceramic fibre yarn twisted ropes, ceramic fibre woolen twisted ropes, ceramic fibre tubing ropes and other products according to the production process, yarn reinforcing materials, and different shapes of ropes section.

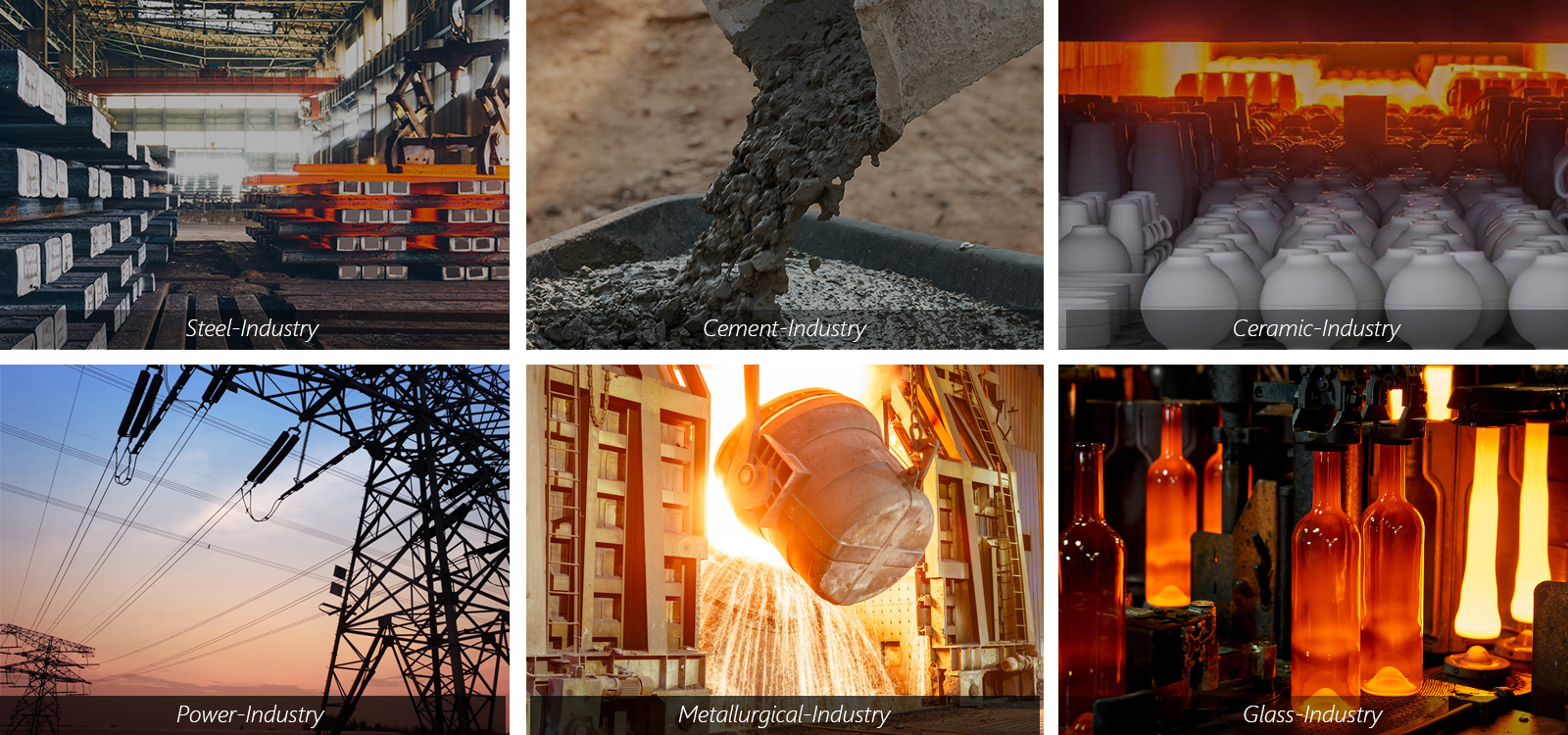

Application of Kerui Ceramic Fiber Products

Ceramic insulation products are mainly used in the metallurgical industry, non-ferrous metal industry, ceramic industry, glass industry, and petrochemical industry. As high-temperature heating furnace backing, low-temperature heating furnace hot surface material, and pipe outer insulation material, it is often used in metallurgical coke ovens, cracking furnaces, ceramic kilns, roller hearth heating furnaces, tunnel kilns, etc.

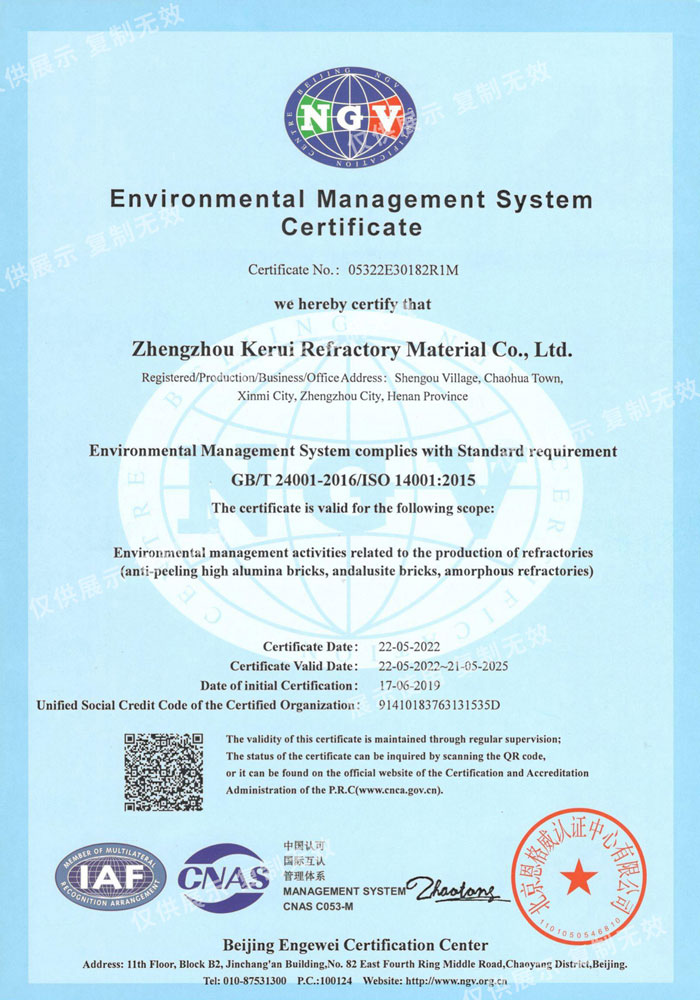

CERTIFICATES OF KERUI REFRACTORY

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

KERUI REFRACTORY PRDUCTS PACKAGING&SHIPPING

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism. If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

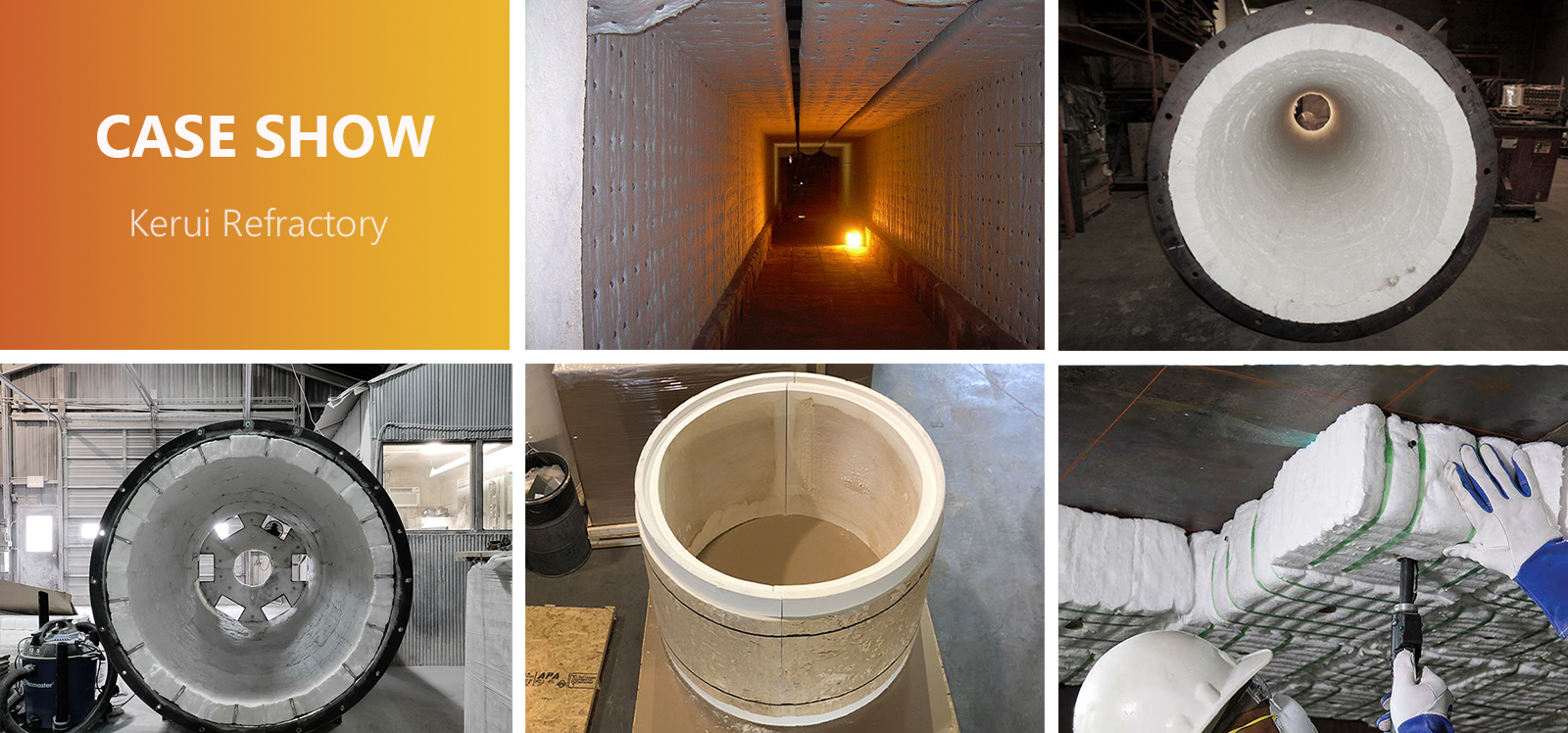

CUSTOMER CASE OF KERUI REFRACTORY

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania. We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ return orders and referrals.

PARTNERS OF KERUI REFRACTORY

Kerui has many customer groups, all of which come from well-known companies in various industries, as well as Fortune 500 companies. Main partners of Kerui Refractory are RUSAL, ALBA, POSCO, SUNSTONE, CHALCO, EGYPTALUM, PSM, SONOCC, CNBMINTERNATIONAL CORP, XING DA STEEL CORD (THAILAND) COMPANY LIMITED, SHANDONG NANSHAN ALUMINIUM CO,. LTD. SHANDONG WEIQIAO VENTURE CO., LTD. and so on.

- One-to-one ServiceExperienced International Sales Manager Provides One-to-one Service

- Professional Solution30+ Technicians Offers Professional Solutions Based on Customers’ Site Conditions

- Quality Management SystemQuality Management System Ensures the Stability of Products

- Responsible After-sales ServiceRegular Customer Visit and Lifelong After-sales Service