Email: market@krceramicfiber.com

Phone/WhatsApp: +86 191 3817 8880

Manufacturing Base:

Chaohua Refractory Industry Zone,Xinmi City, Henan Province, China

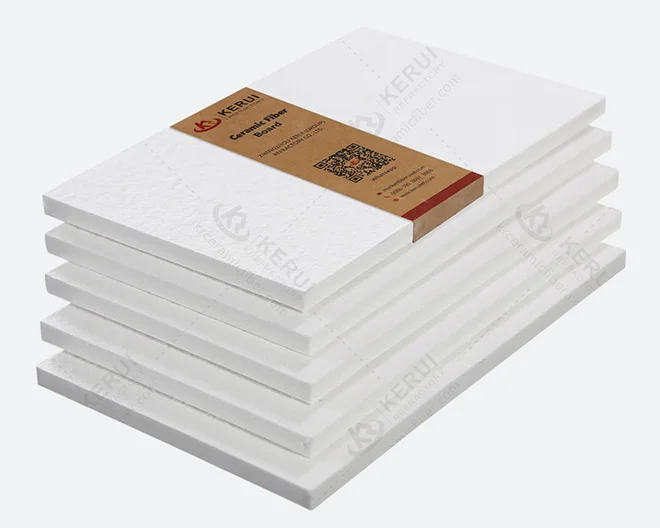

Ceramic fiber board is a kind of refractory material, usually composed of alumina and silicate, and it is also called an aluminum silicate board. Ceramic fiber board is made of ceramic fiber cotton, natural refractory raw materials, and a small amount of organic binder as the main raw materials, and is processed by a fully automated control continuous production line. After heating, it has very good mechanical properties and has a certain hardness support, which provides a strong guarantee for the kiln to save energy and reduce consumption, high quality, and high output.

Ceramic Fibre Blanket is of regular size, combining the functions of fire resistance, heat insulation and heat preservation in one, without any binding agent, with the characteristics of high strength, light weight and good flexibility. The physical property like refractory and insulation keep same when meet with oil,water or steam. Ceramic fiber blanket can be cut into different sizes according to the user needs. They can also be wrapped with aluminum foil on one or both sides to meet the requirements of different industries.

Ceramic fiber cloth is made of ceramic fiber with a certain proportion of organic fiber added, lined with glass fiber (steel wire) and spun into yarn, which is then woven into cloth. Ceramic fibre cloth is characterised by high temperature resistance, low thermal conductivity, resistance to thermal shock and low heat capacity.

Braided ceramic fibre fabrics with a width of less than 100mm are usually referred to as ceramic fibre tapes. Ceramic fibre tape is made of heat-resistant alloy wire or alkali-free glass yarn reinforced with spunlace ceramic fibre yarn. Ceramic fibre tapes have high strength and good flexibility, not only with high temperature insulation properties, but also with the flexibility of ordinary textiles.

Ceramic fibre paper is produced from high purity ceramic fibres plus a small amount of selected binding agent, used in the field of high temperature insulation, advanced production technology makes the distribution of fibres very homogeneous, the thickness and bulk density of the product is controlled precisely, and the binding agent will be completely burned off in the process of use.

Ceramic Fibre Modules are made by experienced craftsmen by folding ceramic fibre blankets or cutting blocks into layers and processing them with specialised equipment. It has the characteristics of reliable quality, quick installation and superior heat preservation performance. It can be applied to the lining of various thermal equipment.

Ceramic fibre ropes are braided from ceramic fibre yarns reinforced with heat-resistant alloy wires or alkali-free glass yarns. Ceramic fibre ropes can be divided into ceramic fibre round braided ropes, ceramic fibre square braided ropes, ceramic fibre yarn twisted ropes, ceramic fibre woolen twisted ropes, ceramic fibre tubing ropes and other products according to the production process, yarn reinforcing materials, and different shapes of ropes section.

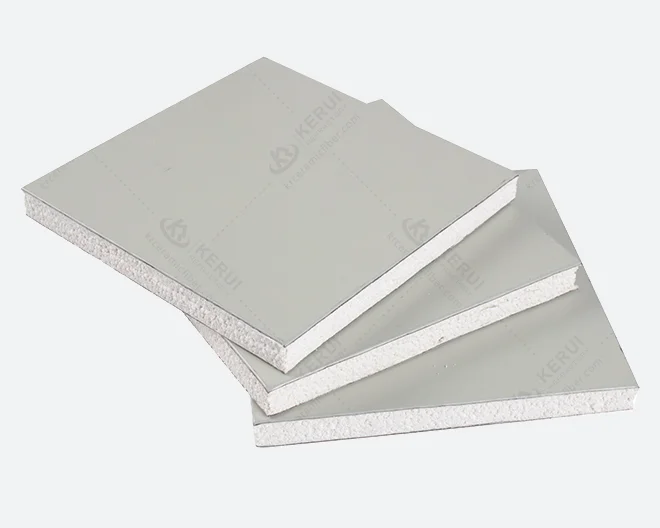

Calcium silicate board (referred to as calcium silicate board), also known as non-asbestos calcium silicate board, microporous calcium silicate board, is a new type of board made of siliceous and calcareous materials with a composition content of >90%, through the pulping, moulding, steam-raising, drying, sanding and post-processing, etc., which is a kind of asbestos-free high-performance thermal insulating material with low weight, high strength, low thermal conductivity, high-temperature, corrosion-resistant, cuttable, turntable, etc., being Widely used in electric power, metallurgy, petrochemical, construction, shipbuilding, cement and other industries, boilers, industrial kilns, heat insulation.

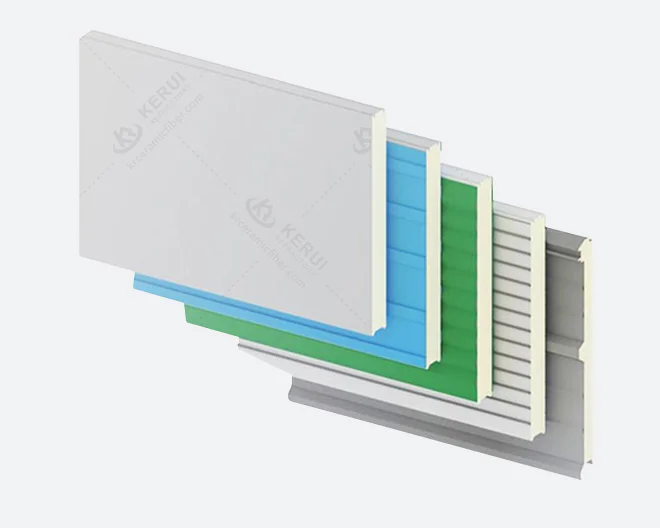

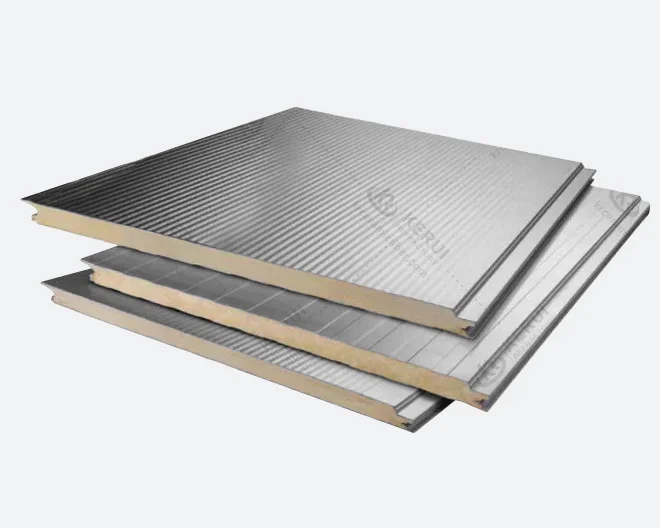

Calcium silicate board (cement fiber board) sandwich panel refers to a sandwich structure composite panel with calcium silicate board or cement fiber board as the panel and various types of foam as the sandwich layer. The foam sandwich layer can be PU, XPS, EPS, etc. Calcium silicate board sandwich panel is suitable for a variety of construction and industrial fields due to its superior fire resistance, moisture resistance and heat insulation performance, and can provide efficient protection and comfort.

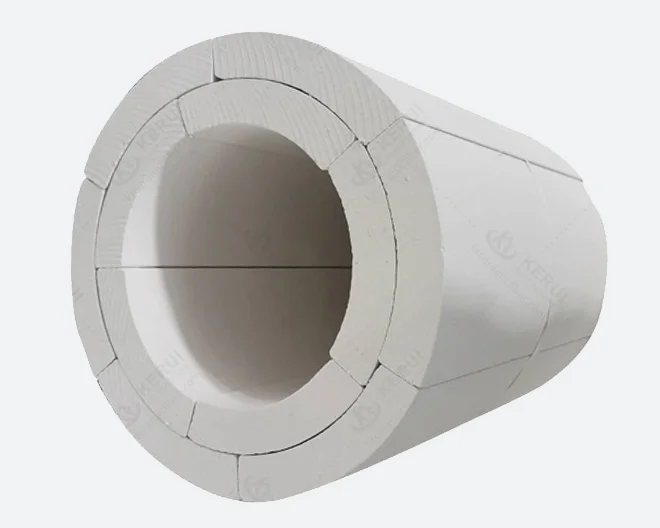

Calcium silicate pipe is a white, hard, and lightweight thermal insulation material. It has high strength, low thermal conductivity, and can withstand high temperatures and corrosion. It can be cut and sawed, making it versatile for use in various industries, including electric power, metallurgy, petrochemical, construction, and shipbuilding.

Sandwich panels are typically made from lightweight materials, with the middle layer providing structural strength and rigidity, while the outer layer provides surface protection. EPS is a lightweight foam material with excellent thermal insulation and shock-absorbing properties. Adding graphite to EPS can significantly improve the material’s thermal and electrical conductivity. The addition of graphite gives EPS better thermal management properties while maintaining a lighter weight.

Soluble fiber blankets are made from alkaline earth silicate fibers. They have a higher fiber content, uniform distribution, and lower thermal conductivity than traditional materials. The fibers are slender and soft, reducing skin irritation. The product is also hydrophobic after special processing.

Bio Soluble Fiber Yarn is yarn-shape high-temperature products which composed of soluble fibers blended with certain percentage organic bulk, reinforced with fiberglass or inconel wire. The bio soluble fiber yarn is generally used to sew fire-proof cloth.

New type of low-carbon, environmental friendly and energy-saving product; no pollution or carcinogenic material was included.

High-performance polyurethane foam is a polyurethane foam material with excellent performance. High-performance polyurethane foam (HPPU) is widely used in construction, automobile, industry and other fields due to its excellent thermal insulation, light weight, high strength, water resistance and flame retardant properties.

Polyurethane sandwich panel is a double metal surface, single metal surface, non-metal surface composite panel with polyurethane rigid foam as the insulation layer. The outer layer provides the structural strength and durability of the panel and can prevent the polyurethane core from getting damp or damaged.

Aerogel insulation board is a rigid, high-efficiency thermal insulation board. The material combines silica aerogel with special fibers to produce a rigid nanopore insulation board with ultra-low thermal conductivity and high temperature resistance. It is suitable for integrated insulation boards in building construction and medium and high temperature industrial equipment.

Aerogel insulation cotton is a flexible insulation material with low density and low thermal conductivity. It is a flexible and highly operable insulation material made on the basis of aerogel after processing. It has extremely high porosity, which makes it have excellent thermal insulation performance. It is formed by combining hydrophobic silica aerogel with a substrate, which is very suitable for the thermal insulation needs of small spaces and can be flexibly mounted on complex surfaces.

Kerui nano thermal insulation board is a new material made by high-tech technology. Special inorganic nano-scale refractory powder forms tiny nano-scale pores, and its thermal conductivity is smaller than that of still air. It is widely used in steel, petroleum, glass, ceramics, electricity and other industries.

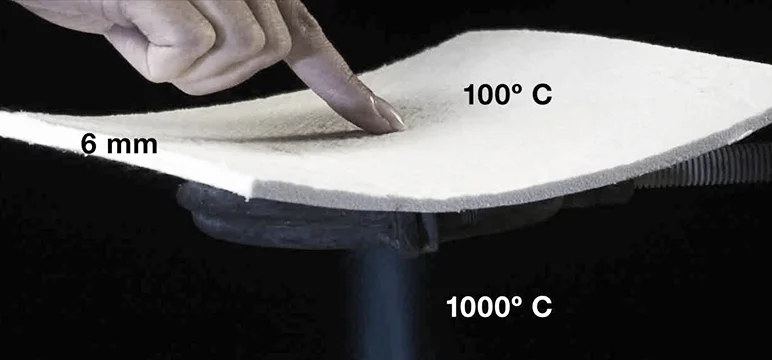

Kerui Nano thermal insulation felt uses lightweight, inorganic nano-SiO2 and ceramic fibers with very low thermal conductivity as raw materials, and aluminum foil with high reflectivity as the bottom material. It adopts a single-layer composite structure through continuous coating and pressing and baking processes. The product has good flexibility, ultra-low thermal conductivity and impact resistance.

Kerui has strict product quality control system. All will be manually inspected before delivery. And each production link can be tracked through the code.

As an original manufacturer in China, Kerui has 20 years of experience. Kerui continues providing excellent products for worldwide customers.

There are overseas business manager, QCS, delivery team, engineer team and other parts in Kerui. The professional team promotes your business greatly.

Throughout the whole cooperation process, Kerui has complete service system with high satisfactory, including pre-sales, during-sales and after-sales.

Iron & Steel

Aluminum

Lead

Zinc

Copper

Cement & Lime

Glass

Power Station

Industrial Boiler

Energy

Chemical Industry