Aerogel Insulation Felt

Aerogel insulation felt is made by combining aerogel and glass fiber. It’s widely used in industries due to its excellent thermal insulation and lightweight properties.

- 650

Maximum operating temperature (℃)

- 180

Bulk Density (kg/m³)

- ≥83

Compression strength (kPa)

- -1.2

Heating permanent line change (%) (≤)

Kerui Aerogel Insulation Felt Technical Data Sheet

| Specifications and models | IIIA aerogel felt | IIIA aerogel roll | IVA aerogel roll | Test standards | |

|---|---|---|---|---|---|

| GB/T 34336-2017 Nanoporous aerogel composite insulation products | |||||

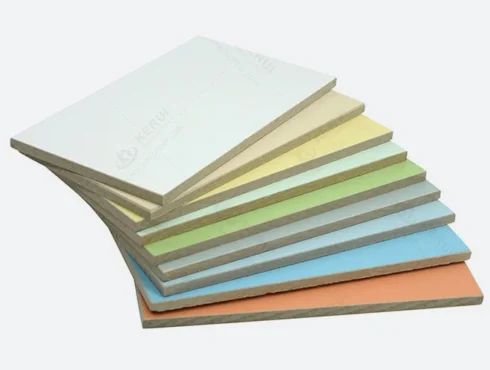

| Appearance | Flexible coiled material, mainly white, color can be customized (the surface should be flat, without scratches, stains, or damage that would hinder use) | GB/T 34336-2017 | |||

| Thickness (mm) | 0.5、1.0、2.0 | 3、5、10、15、20 | / | ||

| Width (mm) | 1500 | / | |||

| Thermal conductivity | Average temperature 25℃ | ≤0.021W/(m·K) | GB/T 10294-2008 | ||

| Average temperature 200℃ | ≤0.027W/(m·K) | ||||

| Average temperature 300℃ | ≤0.035W/(m·K) | ||||

| Average temperature 500℃ | ≤0.065W/(m·K) | ||||

| Volume density (kg/m3) | 180 | GB/T 34336-2017 | |||

| Hydrophobicity | 99.90% | GB/T 10299-2011 | |||

| Combustion level | Level A1 | GB 5464-2010 | |||

| GB/T 14402-2007 | |||||

| Compression strength | ≥83kPa | GB/T 34336-2017 | |||

| GB/T 13480-2014 | |||||

| Compression rebound rate | 99% | GB/T 34336-2017 | |||

| Vibration mass loss | ≤1% | GB/T 34336-2017 | |||

| Maximum operating temperature | 650℃ | 650℃ | 950℃ | GB/T 34336-2017 | |

| GB/T 17430-2015 | |||||

| GB/T 5480-2017 | |||||

| Heating permanent line change | -1.20% | GB/T 17911-2018 | |||

| Corrosiveness (for covering austenitic stainless steel) | Stress corrosion | The blank test specimens did not show any cracks, and the sample specimens did not show any cracks either. | GB/T 17393-2008 | ||

| PH value of leaching solution | 7.4 | GB/T 17393-2008 | |||

| w(SiO32-)+w(Na+) | 0.05% | GB/T 17393-2008 | |||

| JC/T 618-2005 | |||||

Aerogel Insulation Felt

The flexible felt material is made by combining aerogel and glass fiber using the sol-gel in-situ composite process. It is widely used in the fields of petrochemical industry, high-temperature steam pipelines, new energy vehicles and building exterior wall insulation. Aerogel insulation felt has been widely used in power plants, petrochemicals, steam pipelines, high-speed trains, fast-installed houses, and new energy vehicle industries due to its excellent thermal insulation performance and lightweight characteristics.